Table of Contents

ToggleFabricating process for British Reinforced Concrete BRC roll top fence

Making cold drawn steel wires

Cold Drawn Steel Wire is the essential starting point in the fabrication of high-performance wire mesh fencing. Manufactured by pulling hot rolled steel wire rods through precision dies at room temperature, this process significantly enhances the wire’s tensile strength, dimensional accuracy, and surface finish.

Steel wire standards used in (BRC 3D Welded Wire Fence)

The steel wire standards for the BRC Welded Wire Fence are governed by several international guidelines, including ASTM, EN, BS, and AS/NZS. ASTM standards such as A1064, A641, and A123 ensure the steel wire’s material quality, galvanized coating, and corrosion resistance. EN standards like EN 10223-7 and EN 10244-2 cover the specifications for welded wire mesh, detailing wire dimensions, coating requirements, and the mechanical properties of the wire. BS standards, including BS EN 10223-7 and BS 1722-14, specify the requirements for high-security fencing materials, including welded wire mesh, and align with European regulations. AS/NZS standards such as AS/NZS 4534 ensure the wire’s durability in outdoor conditions by defining the hot-dip galvanizing process and coating thickness. These standards guarantee that the steel wire used in the 358 fence offers optimal performance, strength, and long-term corrosion protection.

Welding steel wires

After producing high-strength Cold Drawn Steel Wire, the next critical stage in wire mesh fence manufacturing is Welding Wire Mesh. This step involves accurately positioning longitudinal and transverse wires, then fusing them at their intersections using automated resistance welding machines. The result is a rigid, uniform mesh grid with consistent spacing and excellent strength.

Welding steel wires standards

The welding of steel wires using automatic resistance spot welding complies with key international standards, ensuring global acceptance and high performance. Relevant benchmarks include ASTM A185/A185M (Welded Steel Wire Fabric for Concrete Reinforcement) and ASTM A641/A641M (Zinc-Coated Carbon Steel Wire) for the U.S. market; EN 10223-4 (Steel Wire and Wire Products – Welded Mesh Fencing) for Europe; BS 4482 (Steel Wire for Reinforcement) for the UK; and AS/NZS 4680 (Hot-Dip Galvanized Coatings) for Australia/New Zealand.

Compliance with these standards guarantees weld strength, bending performance, corrosion protection, and dimensional accuracy, making the product suitable for demanding structural, security, and infrastructure applications worldwide.

Making fence post

The third step in wire mesh fence production is Forming the Fence Post, specifically shaping steel banding into a Peach-Shaped Fence Post. This process begins with high-quality galvanized or cold rolled steel strips, which are precision folded and pressed through custom-designed molds to create the signature “peach” profile — named for its rounded, ribbed sides and flat back.

Fence post stadards

The use of Q195/Q235 steel processed through cold roll forming ensures excellent structural precision and mechanical performance. Compliance with GB/T 3091 (China), EN 10219 (Europe), ASTM A500 (United States), and AS/NZS 1163 (Australia/New Zealand) guarantees that the product meets rigorous international standards for strength, dimensional accuracy, and weldability. This multi-standard conformity enables broad applicability in global markets, providing confidence in quality, safety, and long-term durability across diverse construction and engineering projects.

Galvanizing

Once the wire mesh panels are welded and the peach-shaped fence posts are formed, the next crucial step is Galvanizing after fabrication. This process involves coating both the fence panels and posts with a protective layer of zinc.

Galvanizing standards

The use of Q195/Q235 steel processed through cold roll forming ensures excellent structural precision and mechanical performance. Compliance with GB/T 3091 (China), EN 10219 (Europe), ASTM A500 (United States), and AS/NZS 1163 (Australia/New Zealand) guarantees that the product meets rigorous international standards for strength, dimensional accuracy, and weldability. This multi-standard conformity enables broad applicability in global markets, providing confidence in quality, safety, and long-term durability across diverse construction and engineering projects.

Powder spraying

After galvanizing, the final surface treatment step is Powder Coating—also known as Powder Spraying. This process involves electrostatically applying a dry powder onto the galvanized surface of fence panels and posts, then curing it in a high-temperature oven to form a smooth, durable, and weather-resistant finish.

Powder spraying sandards

The coating system meets stringent international quality and durability standards. With a standard thickness of ≥ 60 μm and an optional high-protection range of 80–120 μm, it ensures robust corrosion resistance. Adhesion performance complies with ISO 2409 (Classification 0–1) with no flaking, while impact resistance meets ISO 6272 at ≥ 2.5 Joules. Salt spray testing in accordance with ISO 9227 and ASTM B117 achieves ≥ 500–1000 hours, confirming exceptional resistance to harsh environments. Together, these results guarantee long-term protection, structural integrity, and suitability for demanding industrial, marine, and outdoor applications.

Making cold drawn steel wires

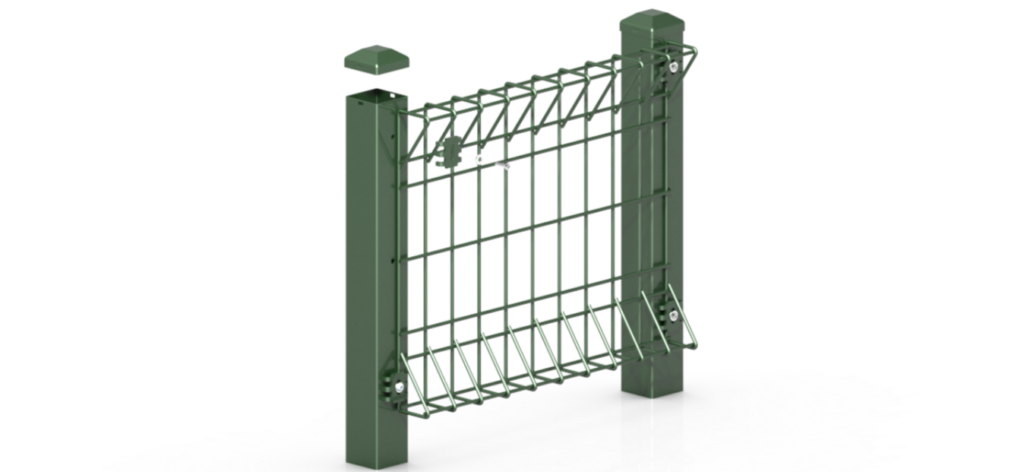

Crafted from cold-formed square posts and BRC steel wire welded mesh, this fence system features a simple yet elegant design with dynamic and smooth lines. The integrated post design connects securely to the mesh using dedicated brackets and anti-theft bolts, ensuring adaptability to uneven terrain and versatile installation angles. Installation options include push-in assembly or sequential installation of the post and mesh, offering a convenient and efficient setup process… read more.

CONTACT US

WhatsApp: +86 138 1087 4664 Email: info@ChinaFenceMaker.com