Table of Contents

ToggleFabricating process for Square tube fence/railing with special shaped post

Making steel pickets

Fabricating square tube fence pickets with galvanized steel square posts is a precise process combining roll-forming, welding, galvanizing, and coating. The result is a durable, rust-resistant, and stylish fence system that is built to last.

Steel standards used in Square tube fence/railing

Square tube fences and railings are manufactured under internationally recognized steel and coating standards to ensure durability, safety, and long service life. In the ASTM system, common references include ASTM A500for structural steel tubing, ASTM A123 for hot-dip galvanizing, and ASTM F2408/F2453 for ornamental fencing performance. The European EN standards often apply EN 10219 for cold-formed structural hollow sections, EN ISO 1461 for galvanizing, and EN 13438 for organic powder coatings. The British Standards (BS) align closely with EN, such as BS EN 10210/10219 for steel tubes and BS EN 1461 for galvanizing. Meanwhile, the Australian/New Zealand standards (AS/NZS) adopt AS/NZS 1163 for structural steel hollow sections, AS/NZS 4792 for galvanizing, and AS/NZS 4506 for protective coatings. By following these standards, square tube fences and railings achieve international compliance, offering strength, corrosion resistance, and consistent quality for global markets.

Welding steel wires

Fabricating square tube fence pickets with galvanized steel square posts is a precise process combining roll-forming, welding, galvanizing, and coating. The result is a durable, rust-resistant, and stylish fence system that is built to last.

Welding steel wires standards

Welding steel tubing fences and railings must follow internationally recognized standards to ensure safety, strength, and long-term performance. In the ASTM system, the key references are ASTM A500 (structural tubing), ASTM A513 (ERW tubing), AWS D1.1 / D1.3 (welding codes), and ASTM F2408 / F2453 (ornamental fence requirements). For European EN standards, manufacturers rely on EN 10219 (cold-formed welded sections), EN 1090-2 (execution of steel structures), and welding qualifications under EN ISO 15614 and EN ISO 9606. In the British Standards (BS) framework, the relevant codes include BS EN 10210 / 10219 (structural hollow sections), BS 4872 (welder approval), and BS EN ISO 5817 (weld quality). Meanwhile, the Australian/New Zealand standards (AS/NZS) adopt AS/NZS 1163 (structural hollow sections), AS/NZS 1554.1 (welding of steel structures), and AS/NZS 5131 (fabrication and erection of steel structures).

By adhering to these standards — ASTM A500, A513, F2408, F2453, AWS D1.1/D1.3; EN 10219, 1090-2, ISO 15614, ISO 9606; BS 10210, 10219, 4872, ISO 5817; and AS/NZS 1163, 1554.1, 5131 — welded steel tubing fences and railings achieve consistent quality, high structural integrity, and global compliance.

Making fence post

The third step in wire mesh fence production is Forming the Fence Post, specifically shaping steel banding into a Peach-Shaped Fence Post. This process begins with high-quality galvanized or cold rolled steel strips, which are precision folded and pressed through custom-designed molds to create the signature “peach” profile — named for its rounded, ribbed sides and flat back.

Fence post standards

The use of Q195/Q235 steel processed through cold roll forming ensures excellent structural precision and mechanical performance. Compliance with GB/T 3091 (China), EN 10219 (Europe), ASTM A500 (United States), and AS/NZS 1163 (Australia/New Zealand) guarantees that the product meets rigorous international standards for strength, dimensional accuracy, and weldability. This multi-standard conformity enables broad applicability in global markets, providing confidence in quality, safety, and long-term durability across diverse construction and engineering projects.

Galvanizing

Once the wire mesh panels are welded and the peach-shaped fence posts are formed, the next crucial step is Galvanizing after fabrication. This process involves coating both the fence panels and posts with a protective layer of zinc.

Galvanizing standards

The use of Q195/Q235 steel processed through cold roll forming ensures excellent structural precision and mechanical performance. Compliance with GB/T 3091 (China), EN 10219 (Europe), ASTM A500 (United States), and AS/NZS 1163 (Australia/New Zealand) guarantees that the product meets rigorous international standards for strength, dimensional accuracy, and weldability. This multi-standard conformity enables broad applicability in global markets, providing confidence in quality, safety, and long-term durability across diverse construction and engineering projects.

Powder spraying

After galvanizing, the final surface treatment step is Powder Coating—also known as Powder Spraying. This process involves electrostatically applying a dry powder onto the galvanized surface of fence panels and posts, then curing it in a high-temperature oven to form a smooth, durable, and weather-resistant finish.

Powder spraying standards

The coating system meets stringent international quality and durability standards. With a standard thickness of ≥ 60 μm and an optional high-protection range of 80–120 μm, it ensures robust corrosion resistance. Adhesion performance complies with ISO 2409 (Classification 0–1) with no flaking, while impact resistance meets ISO 6272 at ≥ 2.5 Joules. Salt spray testing in accordance with ISO 9227 and ASTM B117 achieves ≥ 500–1000 hours, confirming exceptional resistance to harsh environments. Together, these results guarantee long-term protection, structural integrity, and suitability for demanding industrial, marine, and outdoor applications.

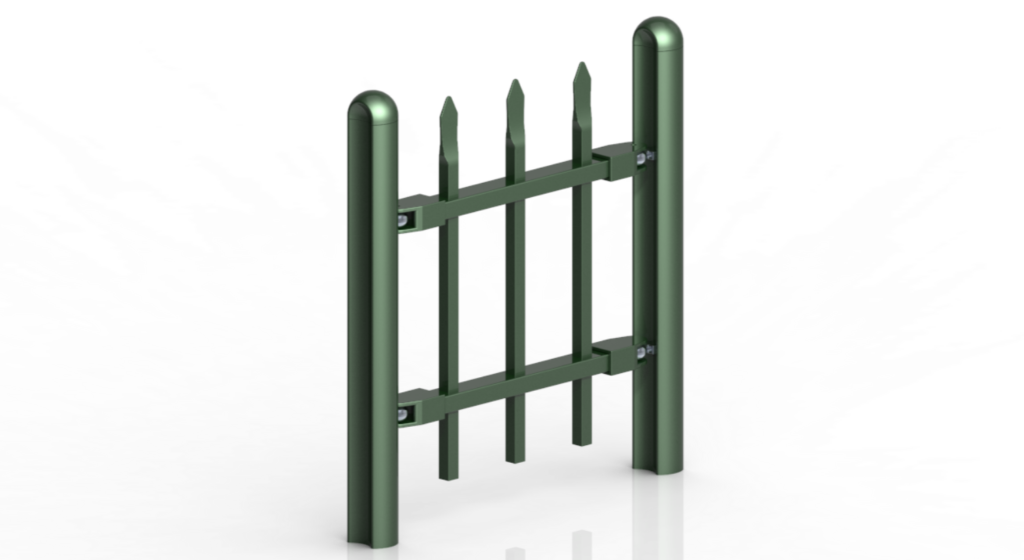

Square tube fence/railing with special shaped post

The YR Special Shaped Post Railing features special-type posts and welded square tube fence panels, assembled with universal die-cast aluminum connectors and post caps. Its streamlined design combines traditional Oriental aesthetics with modern stability, creating a visually elegant and stable structure. The unique universal hinge connection design between the posts and fence panels allows for flexible installation at various angles. The surface is treated with hot-dip galvanizing and electrostatic powder coating, offering superior anti-corrosion performance … read more.

CONTACT US

WhatsApp: +86 138 1087 4664 Email: info@ChinaFenceMaker.com