Table of Contents

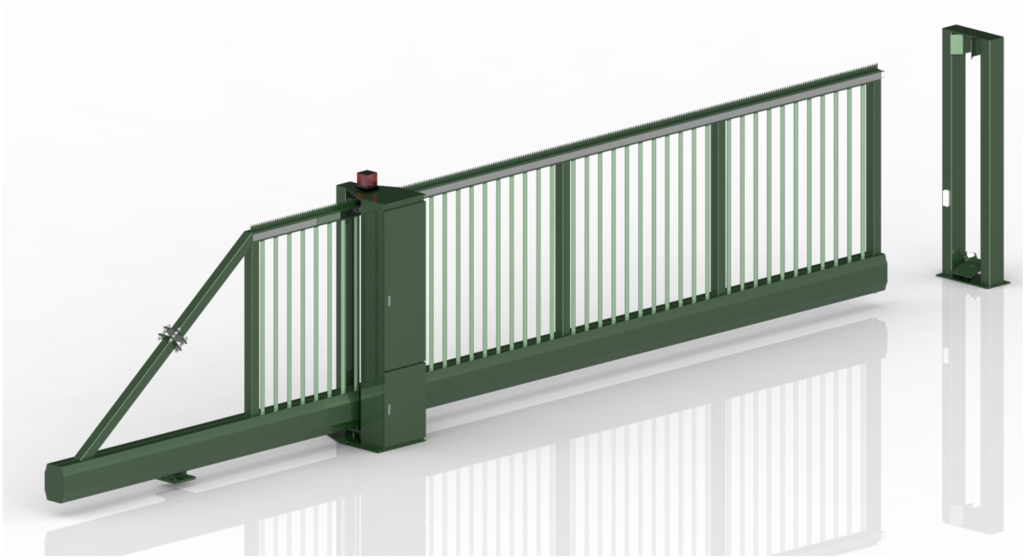

ToggleFabricating process for TCG-Trackless Cantilever Gate

Making gate post

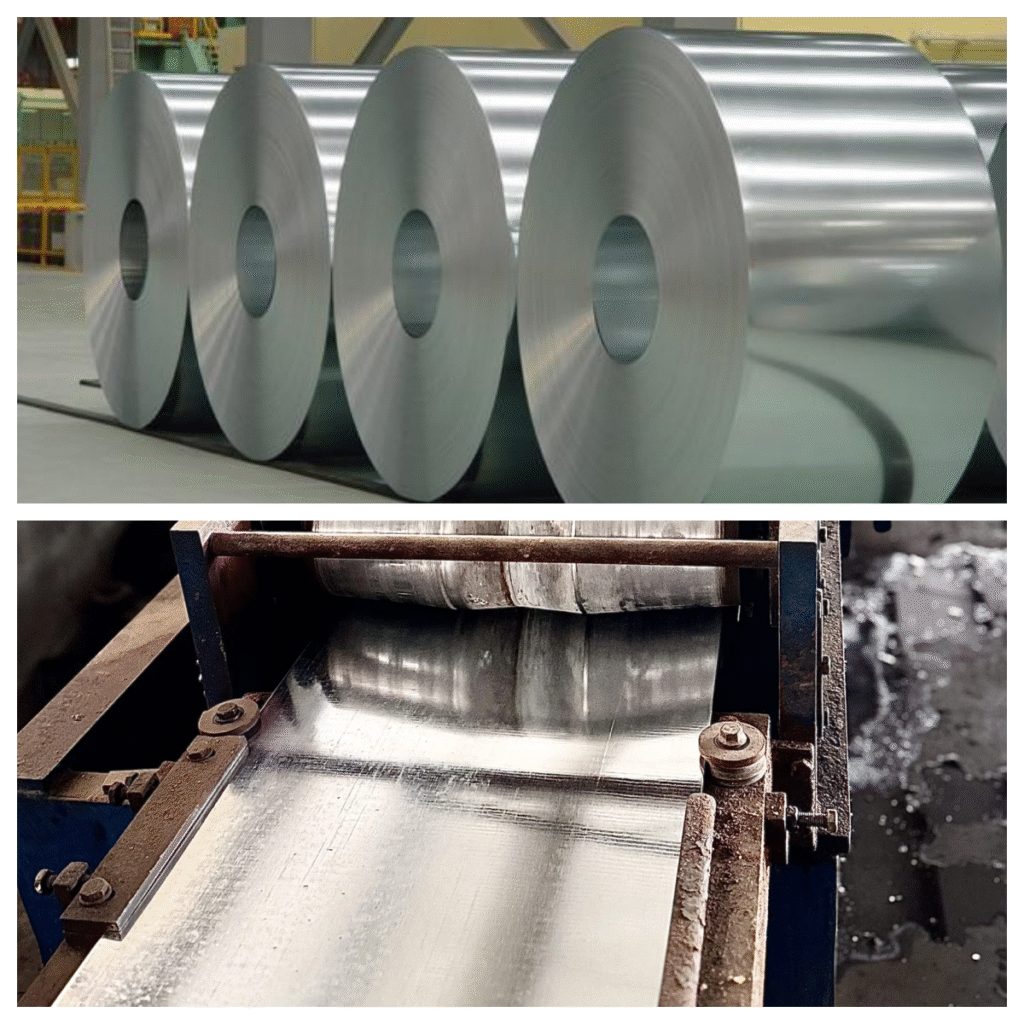

The first step is Forming the Gate Post, specifically shaping steel banding into a Peach-Shaped Fence Post. This process begins with high-quality galvanized or cold rolled steel strips, which are precision folded and pressed through custom-designed molds to create the profile.

Making gate post and panel standards

Gate posts and fence panels are manufactured under a combination of structural steel standards (ASTM A36, EN 10025), welding standards (ASTM F2453, EN 1090), and coating standards (ASTM A123, EN ISO 1461). In practice, ASTM, EN, BS, and AS/NZS systems all ensure that gates and posts meet international strength and corrosion-resistance requirements, making them suitable for industrial, commercial, and residential fencing projects.

Welding

After producing gate panels, the next critical stage in gate manufacturing is Welding. This step involves accurately positioning longitudinal and transverse tubes, then fusing them at their intersections using automated resistance welding machines. The result is a rigid, uniform mesh grid with consistent spacing and excellent strength.

Welding standards

For trackless cantilever gates, welding must follow structural steel codes like AWS D1.1 (U.S.), ISO 3834 + ISO 9606-1 (global), and EN 1090 (Europe). Welds must also meet inspection standards (ISO 17637, ISO 5817) to guarantee strength and safety. After welding, ASTM A123 / EN ISO 1461 galvanizing ensures long-term corrosion resistance.

Galvanizing

For Trackless Cantilever Gates, the galvanizing process follows surface preparation → pickling → fluxing → hot-dip zinc bath → cooling → inspection. The key international standards are ASTM A123 (U.S.), EN ISO 1461 (EU), and AS/NZS 4680 (AU/NZ). When combined with powder coating (duplex system), gates achieve superior corrosion resistance, mechanical strength, and long service life, even in harsh industrial or coastal environments.

Galvanizing standards

Trackless Cantilever Gates are manufactured under multiple international standards to ensure strength, safety, and durability:

-

Steel & Structural Standards → ASTM A36 / A500 (U.S.), EN 10025 / EN 10210 (EU) for posts and frames.

-

Welding Standards → AWS D1.1 (U.S.), ISO 3834 + ISO 9606-1 (International), EN 1090 (EU) for welded gate structures.

-

Wire/Panel Standards (if mesh infill used) → ASTM F2453 / A1064, EN 10223-7.

-

Galvanizing & Coating Standards → ASTM A123 (U.S.), EN ISO 1461 (EU), AS/NZS 4680 (AU/NZ), plus ASTM A780 for repair at welds.

-

Fittings & Accessories → ASTM F934 (U.S.), BS 1722 (UK).

Powder spraying

After galvanizing, the final surface treatment step is Powder Coating—also known as Powder Spraying. This process involves electrostatically applying a dry powder onto the galvanized surface of fence panels and posts, then curing it in a high-temperature oven to form a smooth, durable, and weather-resistant finish.

Powder spraying standards

The coating system meets stringent international quality and durability standards. With a standard thickness of ≥ 60 μm and an optional high-protection range of 80–120 μm, it ensures robust corrosion resistance. Adhesion performance complies with ISO 2409 (Classification 0–1) with no flaking, while impact resistance meets ISO 6272 at ≥ 2.5 Joules. Salt spray testing in accordance with ISO 9227 and ASTM B117 achieves ≥ 500–1000 hours, confirming exceptional resistance to harsh environments. Together, these results guarantee long-term protection, structural integrity, and suitability for demanding industrial, marine, and outdoor applications.

Making cold drawn steel wires

The TCG Trackless Cantilever Sliding Gate combines cutting-edge industrial design and manufacturing technology. It features a self-supporting structure, a high-strength and corrosion-resistant manganese steel substrate for the bottom beam, and a world-class dedicated sliding gate motor with an advanced control system. Multiple anti-corrosion treatments and high-adhesion polyester powder coating technology ensure long-lasting durability. Leading the industry in terms of environmental protection, aesthetic appeal… read more.

CONTACT US

WhatsApp: +86 138 1087 4664 Email: info@ChinaFenceMaker.com