Table of Contents

ToggleFabricating process for Security and protection guardrail

Making guardrail pipe

The pipe clamp guardrail forming process follows a clear industrial workflow: from raw pipe cutting, deburring, and bending, to clamp fabrication, drilling, galvanizing/powder coating, and final assembly. Unlike welded guardrails, this modular system relies on mechanical clamps that make installation faster, safer, and more flexible.

With hot-dip galvanizing or powder coating, the pipes gain long-term corrosion resistance, ensuring durability for both indoor and outdoor applications. The process results in a versatile, maintenance-friendly guardrail solution that meets modern safety standards while remaining cost-effective for clients worldwide.

Fence pipe standards

Clamp-type guardrail pipes are manufactured and certified under different regional standards, but they all focus on three key aspects:

-

Pipe Material & Dimensions – ASTM A53/A500 (USA), EN 10255 (EU), BS EN 39/10255 (UK), AS/NZS 1163 (AU/NZ).

-

Surface Protection – Hot-dip galvanizing and coatings governed by ASTM A123, EN ISO 1461, AS/NZS 4680.

-

Safety & Load Requirements – OSHA 1910.29 (USA), BS 6180 (UK), EN 14122/13374 (EU), AS 1657 (AU/NZ).

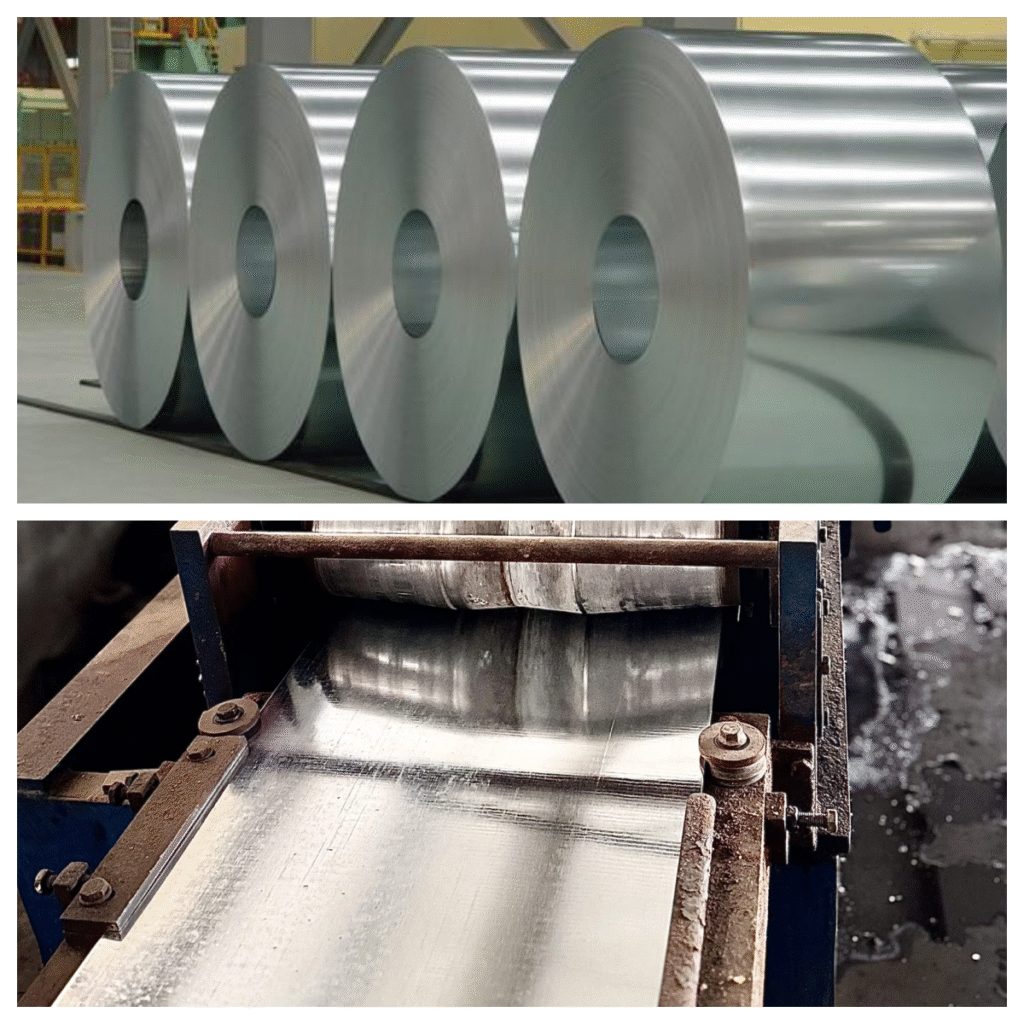

Galvanizing

Once the guardrail pipes are formed, the next crucial step is Galvanizing after fabrication. This process involves coating both the fence panels and posts with a protective layer of zinc.

Galvanizing Standards

The pipe galvanizing process is a carefully controlled sequence of cleaning, pickling, fluxing, and dipping steel pipes into molten zinc to create a durable, corrosion-resistant coating. By forming a metallurgical bond between steel and zinc, hot-dip galvanizing ensures long service life, excellent protection against rust, and low maintenance costs.

Compared with painting or other coatings, galvanizing offers superior durability, self-healing protection, and cost efficiency, making it the preferred surface treatment for guardrail pipes, fencing, and structural applications worldwide.

Powder spraying

After galvanizing, the final surface treatment step is Powder Coating—also known as Powder Spraying. This process involves electrostatically applying a dry powder onto the galvanized surface of fence panels and posts, then curing it in a high-temperature oven to form a smooth, durable, and weather-resistant finish.

Powder spraying standards

The coating system meets stringent international quality and durability standards. With a standard thickness of ≥ 60 μm and an optional high-protection range of 80–120 μm, it ensures robust corrosion resistance. Adhesion performance complies with ISO 2409 (Classification 0–1) with no flaking, while impact resistance meets ISO 6272 at ≥ 2.5 Joules. Salt spray testing in accordance with ISO 9227 and ASTM B117 achieves ≥ 500–1000 hours, confirming exceptional resistance to harsh environments. Together, these results guarantee long-term protection, structural integrity, and suitability for demanding industrial, marine, and outdoor applications.

Clamps part

Clamp parts are produced through casting/forging, heat treatment, machining, and galvanizing, ensuring high strength and corrosion resistance. With modular designs, these clamps allow quick, weld-free assembly of guardrails and safety barriers, making them ideal for industrial, construction, and public safety use.

Clamp standards

Clamp parts for guardrail systems are governed by a combination of material, coating, and safety standards across different regions.

-

Material standards (ASTM A47, EN 1562, BS EN 10242) ensure the clamps are cast or forged with reliable strength.

-

Coating standards (ASTM A153, EN ISO 1461, AS/NZS 4680) guarantee long-term corrosion protection.

-

Safety standards (OSHA 1910.29, BS 6180, EN 14122, AS 1657) define guardrail performance, load capacity, and installation requirements.

AG Safety and Security Guardrail

The safety barrier is assembled from BGP series pipe clamp fittings and international pipe materials. The surface can be treated with hot-dip galvanizing and electrostatic spraying after hot-dip galvanizing. Commonly used pipes include DN20, DN25, DN32, and DN40. Widely used for safety protection of industrial plants, platforms, equipment, columns, corners, roof anti falling safety protection, chemical equipment safety protection, water treatment equipment and pool protection, supermarket safety protection, etc … read more.

CONTACT US

WhatsApp: +86 138 1087 4664 Email: info@ChinaFenceMaker.com